CONTACT:

VALUE-ADDED DISTRIBUTOR

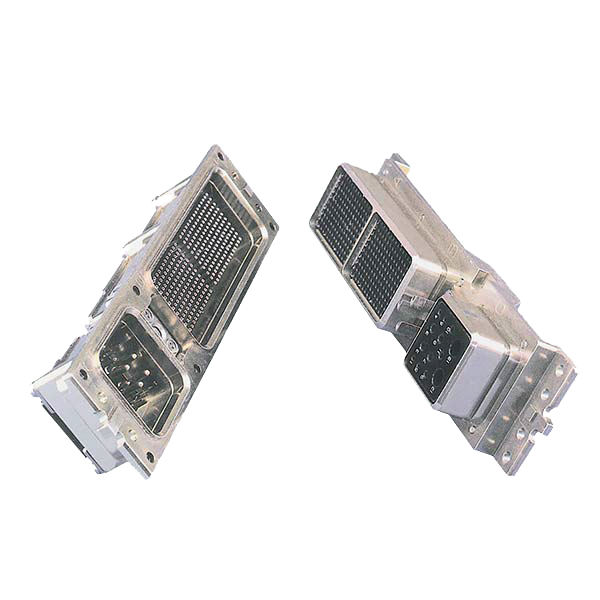

ARINC 600

ARINC 600 Connectors are recognized standard rack and panel connectors for Aircraft applications. The ARINC 600 is the successor to the ARINC 404 for many of the new avionics designs. Compared to the ARINC 404, the ARINC 600 features lower mating force contacts, increased contact count, and a front release, floating keying system. Amphenol’s extensive product offering will meet the most demanding needs of our customers. At the design-in stage, Amphenol’s sales engineers will work with you to select a connector from our standard product line or coordinate the design of an application-specific connector. Amphenol’s ARINC 600 rack and panel connectors are designed to meet all relevant ARINC 600 connector specifications.

FEATURES AND BENEFITS

- Low insertion force contacts

- Both environmental and non-environmental versions

- Front removable keying posts

- Field replaceable inserts for size 22 and power contacts

- Up to 800 sizes 22 contact positions in one connector

- Crimp, coaxial, power, printed circuit, and wire wrap contacts

- Waveguide connections

MARKETS

DOCUMENTS

RELATED PRODUCTS

FILTER CONNECTORS

- Reduced inspection and assembly labor

- High-frequency EMI performance superior to a board-level filter solution

- Superior shielding effectiveness

- Solderless design

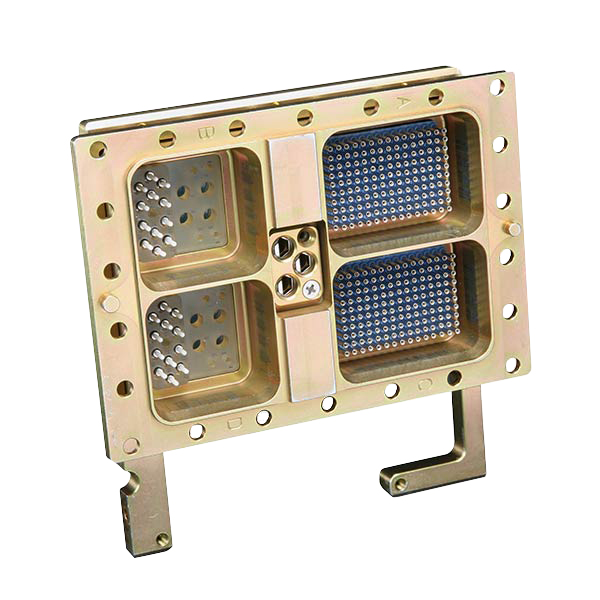

TERMINATION MODULES

- Eliminates exposure of connector to soldering and cleaning process

- Allows for easy repair of damaged socket contacts

- Easy installation and removal from motherboard facilitates repair and rework

- Guideposts guarantee proper alignment during installation

- Optional rubber interfacial seal protects the connector from the environment

BACKSHELLS

- Provides strain relief and EMI shielding

- Multiple cable entry points available

- Custom configurations available

| PERFORMANCE SPECIFICATIONS | |

| Dielectric withstanding voltage (DWV): | 1500 Vrms, 500 Vms @ 50,000 ft. (15,240m) |

| Contact continuous current ratings: |

Size 22 - 5.0A: Size 20 - 7.5A |

| Contact Resistance: | |

| Size 22: | 8.0 milliohms, initial (max.), 11.0 milliohms, conditioned (max.) |

| Size 20: | 7.0 milliohms, initial (max.), 8.5 milliohms,conditioned (max.) |

| Size 16: | 3.5 milliohms, initial (max.), 5.0 milliohms, conditioned (max.) |

| Size 12: | 2.0 milliohms, initial (max.), 2.5 milliohms, conditioned (max.) |

| Insulation resistance: | 5.0 gigaohms min. at 500 VDC |

| Engagement/separation force: | Shell size 1 - 27 Ibs. (120N) max. Shell size 2 - 60 Ibs. (267N) max. Shell size 3 - 105 Ibs. (467N) max. |

| Durability: | 500 cycles min. - mating & unmating |

| Temperature range: | -65°C (-86° F) to +125°C (+275° F) |

| Fluid immersion (Class A only) resistance: | (1) Hydraulic fluid per MIL-H-5606 (2) Lubricating oil (synthetic) per MIL-L-23699 (3) 1:3 mix of isopropyl alcohol & mineral spirits per FED. SPECS. TT-I-735 &TT-T-291 respectively |

| Vibration: | MIL-STD-1344, Method 2005.1, condition value E: random - 16.4G minimum severity: 8 hours in each of 3 mutually perpendicular planes with 100mA electrical load. No visible damage, breakage, cracking or loosening of parts and no discontinuities exceeding 1 microsecond. |

| Shock: | MIL-STD-1344, Method 2004.1, test condition A: Three shocks in each direction along each of 3 axes, mutually perpendicular to each other. No visible damage, breakage, cracking or loosening of parts and no discontinuities exceeding 1 microsecond. |

| MATERIAL SPECIFICATIONS | ||

| Description | Material | Finish |

| Shell and Backshell | Aluminum Alloy or Composite | "Electroless Nickel, Chem Film (Mil-C-5541, Class 3), RoHS Chem Film (MIL-DTL-5541, Type II, Class 3) OD Chromate, Tin, Gold, Zinc Nickel, Yellow CAD or Nickel Fluorocarbon Polymer (Durmalon)" |

| Hardware & Polarizing Keys | Stainless Steel | Passivated or Nickel Plated |

| Inserts | Thermoset or Thermoplastic | -- |

| Aluminum Alloy | Nickel Plated | |

| Grommets & Face Seal | Fluorosilicone Elastomer | -- |

| EMI Spring | Copper Alloy | Nickel Plated, Gold |

| O-Ring | Fluorosilicone Elastomer | -- |

| Contacts | Copper Alloy | Gold over Nickel, Solder Dipping is available in both RoHS and non-RoHS Compliance |

ARINC 600 Catalog

ARINC 600 Catalog